The maintenance of proper swimming pool water chemistry is of the utmost importance in ensuring that a safe and balanced state. Even though the water in a pool seems crystal clear it may contain harmful bacteria. This guide will explain the necessity for chemical treatments in swimming pools, the categories of pool sanitation and some of the issues involved in the use of dosing pumps.

There are two mains aspects of pool water chemistry: water sanitation and water balance.

Water Sanitation

All kinds of bacteria, some of them potentially hazardous to health, can breed rapidly in swimming pools. Therefore it is necessary to disinfect the water for the safety of bathers. Chlorine is the most commonly employed disinfectant in the UK, and there are chlorine-based alternatives too. The correct level of chlorination has to be constantly maintained. The following chemicals are typically used for water sanitation.

Water Balance

- Disinfectants/sanitisers: to kill bacteria.

- Algaecides: to destroy build-up of algae.

- Filter aids, flocculents and clarifiers: to remove debris.

The most important of several factors in water balance is its pH measurement: the levels of acidity and alkalinity in the water.

These chemicals are used in treating pH balance.

Testing pH Balance

- Sodium ash (sodium carbonate) or pH Plus: to increase pH level.

- Sodium bisulphate or pH Minus: to reduce pH level.

- Chlorine stabiliser: to prevent loss of chlorine.

The pH scale is from zero (strong acid) to 14 (strong alkali), and the neutral (neither acidic nor alkaline) is 7. The optimum pH for a swimming pool is between 7.2 and 7.6, this range being the most comfortable for swimmers’ eyes. This level also provides the ideal environment for chlorination, and promotes the prevention of corrosion and limescale build-up due to insufficient or excess hardness of the water. Many affordable portable test kits are on the market, typically comprised of strips, tablets, liquid reagents or handy digital meters to gauge Total Alkalinity (the measure of the water’s resistance to changes in pH) and levels of chlorine and cyanuric acid. Checks should be made daily.

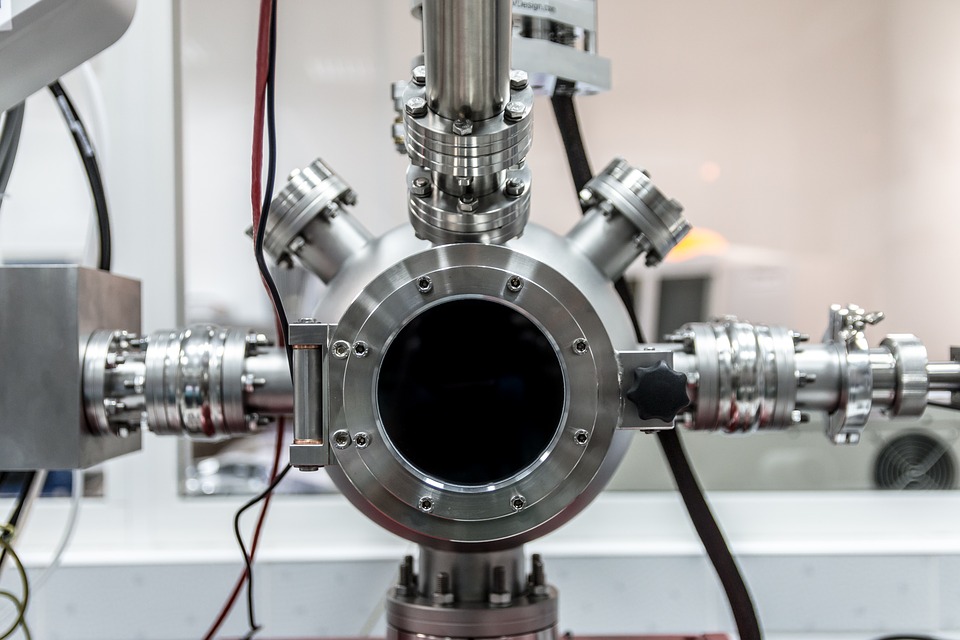

Dosing Pumps

A dosing pump delivers chlorine or other anti-bacterial treatments into the water at a steady, controlled rate. A good pump will regulate rate and amount of discharge, fluid temperature and working pressure, and can be connected to a water meter, boiler feed pump or controller. There should also be a timer and a manual on/off control.

A popular alternative is salt water chlorination. A pump system with an electrolytic stage that breaks down the salt (sodium chloride) dispels it into the water, where it forms chlorine. Some systems include a pH monitor.

Gaffey are a leading supplier of dosing pumps.